There are more than 3 billion Platform-Train-Interface (PTI) events as trains enter and despatch stations, and passengers board trains. The Rail Safety and Standards Board reports: ‘The risk to passengers at the Platform Train Interface (PTI) is equivalent to nearly 13 fatalities each year, and 48% of the total passenger fatality risk on the mainline railway network.’

The safe management of these PTI events is critical as trains and people come together and interact. This is where our Driver Controlled Operation (DCO) system comes into play as it facilitates the safe boarding and alighting of passengers.

Here we provide an insight into our Driver Controlled Operation system, how it works and most notably its role in minimising platform dwell time and enhancing passenger safety.

What is Driver Controlled Operation?

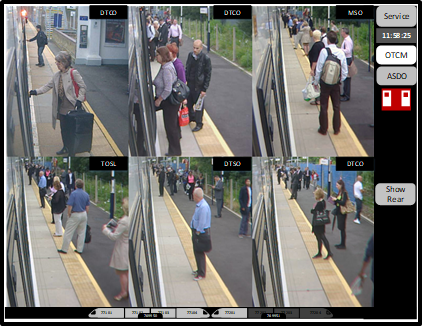

In reference to passenger rail, Driver Controlled Operation (DCO) is where the train driver is in control of opening and closing the train’s doors and train movement. Part of our range of eyeTrain technology, our DCO is a digital, camera-based system which displays clear, live images of each doorway to the train driver on the in-cab monitor (ICM), acting as the Human Machine Interface (HMI) for the Petards Rail system.

How does the Petards Rail DCO work?

Our DCO system comprises wide, dynamic range digital cameras, which are affixed to the exterior of a train and feed images to the ICM. The images shown on the ICM, through our DCO system, are images covering the full train length of the platform which can then be viewed by the train driver and even the train crew in the non-active cab. These images are used to show who, if anyone, on the platform is between the yellow line and the train doors. This corridor is required to be free from passengers before the train can be safely dispatched from the station by the driver.

For the train driver or crew to safely dispatch the train from the platform with a DCO system, the driver must be able to trust the images they see on the ICM. The safety checks offered by our system include image protection for frozen, latent and dropped frames, and a guaranteed end to end latency of less than 600ms.

What’s more, images are cross checked at multiple points with location and metadata. This ensures the driver only sees live footage. An indicator on the monitor is also present to inform the driver that only live images are shown on the ICM.

These features provide our DCO system with a significant safety advantage over platform mounted mirrors or screens as the train driver can continue to monitor the side of the train for possible hazards after station departure.

The features don’t stop there...

Our DCO system also boasts:

- Camera modules, which are designed to perform in harsh conditions, are supplied in robust IP66 minimum sealed enclosures with internal, anti-condensation heating.

- Images that are captured contain timestamps, location and metadata, and are cross-checked at multiple points to ensure the driver sees accurate footage.

- Connectivity with our eyeTrain Connect software which allows users to monitor and analyse status, condition and positional data in real time.

- Intelligent display capable of supporting a 12-car train which can also host GUI from third party systems such as Passenger Information Systems (PIS).

- Modularity for assisting in roadmap planning and rolling out fleet systems.

- Up to SIL 2 rated solution.

Ensuring safe travels

We are proud to say that Petards Rail can certify our Driver Controlled Operation system to EN 50128 SIL 2. Having a DCO system with the required Safety Integrity Level (SIL) rated safety checks, such as this, is essential as it ensures that the driver will only see live images of the platform corridor.

What are Safety Integrity Levels?

The overarching standard is IEC 61508 which is a general SIL standard designed to cover critical safety systems. For the rail industry a series of sub standards were produced based off the original IEC 61508.

- EN 50126 – Reliability, Availability, Maintainability and Safety (known as RAMS)

- EN 50716 – SIL requirements for software

- EN 50129 – SIL requirements for hardware, installation and overall system.

By meeting these rail standards, the IEC 61508 standard is also met.

SIL is identified for critical safety functions. For train operations a wide range of SIL levels can be identified from SIL 1 to SIL 4. In most DCO applications a SIL 2 rating is required based off an in-depth risk assessment and hazard evaluation. The SIL approach is in essence a methodology for addressing risk and as such can be applied to many applications.

What does this mean for the DCO?

A DCO system that doesn’t have the safety features noted above, and SIL 1 or SIL 2 certification, runs the risk of the driver seeing non-live images. This can lead to the belief that the corridor between the yellow line on the platform and the train doors is clear which could potentially lead to serious harm to any passengers in this area.

In addition to EN 50128 SIL 2, our Driver Controlled Operation system also complies with:

- UK Rail Group Standard RIS-2703-RST

- EN 50155

- EN 50121

- EN 50125

Safety is at the heart of everything we do. With our compliant, robust and proven effective DCO technology, the operator and driver can confidently rely on the images they are viewing on the ICM, ensuring safe boarding and alighting during the dispatch procedure.

Driving innovation

At Petards Rail we are proud of our intelligent train technology and the role this can play in streamlining rail operations and saving lives. To ensure we are delivering the most advanced assets and the most impact, we are committed to continual innovation and investing in the progression of our technology.

Our latest and lifesaving innovation is the PTeye which is designed to support in the prevention of PTI incidents. The PTeye system which incorporates the latest in AI-ready technology has been developed to prevent trap and drag incidents before train dispatch and, as a secondary safety measure, to detect drag. Find out more about the PTeye system here >

Contact our team to find out more about our DCO system and how it can enhance your rail operations.

Sources

Rail Safety and Standards Board, Platform Train Interface, https://www.rssb.co.uk/what-we-do/key-industry-topics/platform-train-interface

International Electronical Commission, Safety and functional safety, Safety and functional safety | IEC